The construction equipment rental industry plays a vital role in facilitating construction projects across the world. Renting equipment provides contractors flexibility and reduces upfront capital costs compared to outright equipment purchases. This allows construction companies of all sizes to access the tools they need to complete jobs on time and on budget.

The main benefits of starting a construction equipment rental business include:

- Steady cash flow from regular rental income

- High profit margins after covering equipment and operating costs

- Low overhead compared to manufacturing businesses

- Ability to serve the needs of a wide range of construction contractors

What is a Construction Equipment Rental Business?

A construction equipment rental business involves renting out heavy machinery and tools used for construction projects. Some common examples of rental equipment include:

| Equipment | Uses |

|---|---|

| Excavators | Excavation, grading, trenching |

| Bulldozers | Clearing, grading, landscaping |

| Loaders | Material handling, excavation |

| Forklifts | Lifting, loading, unloading heavy items |

| Compactors | Compacting soil, gravel, asphalt |

| Scissor Lifts | Access to high places for work |

| Dump Trucks | Hauling dirt, gravel, demolition waste |

| Concrete Equipment | Pumping, placing, finishing concrete |

Equipment rentals are essential for projects involving earthworks, infrastructure, utilities, buildings, roads and more. Contractors rely on rentals to handle short-term equipment needs in a flexible, cost-effective way.

12 Steps to Starting Your Construction Equipment Rental Business

Step 1: Conduct Thorough Market Research

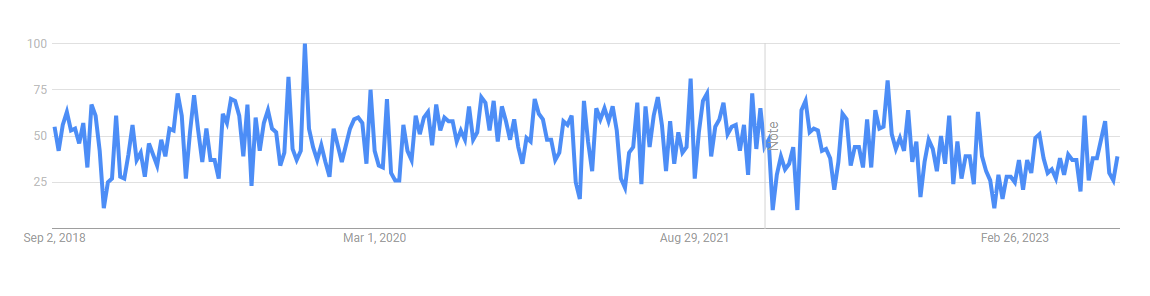

Before investing time and money into starting a rental company, it’s essential to research the market potential in your local area.

Identify high-growth construction industry sectors and projects coming up. For example, focus on infrastructure if your state is investing heavily in roads/bridges.

Study competing equipment rental businesses – location, fleet sizes, specializations, rates etc. to understand opportunities.

Talk to local contractors to gauge equipment needs, pain points with current suppliers and willingness to use your new business.

Examine industry reports and construction forecasts to ensure long term demand for rentals in your market.

Thorough advance research reduces startup risks and positions your company to capture demand effectively.

Step 2: Create a Smart Business Plan

With insights from your market research, develop a comprehensive business plan laying out your:

Company overview – Vision, mission, legal structure, location etc.

Market analysis – Size and growth of local construction sector, competitive landscape assessment.

Operations plan – Rental processes, maintenance schedules, staffing, location features.

Marketing strategy – Promotional tactics, competitive advantages, USPs to advertise.

Financial projections – Startup capital needs, equipment purchase/rental costs, revenue and profit forecasts over 3-5 years based on expected orders and rental rates.

Funding requirements – Sources of startup capital like loans, investors to finance equipment/operations

An in-depth business plan secures buy-in from investors/lenders and guides all strategic decisions as your company develops.

Step 3: Choose an Optimal Business Structure

Popular entities for equipment rentals include sole proprietorship, partnership, LLC or S-corp based on several factors:

Liability – LLC offers liability protection for owners unlike sole props.

Taxation – S-corps, LLCs pass profits/losses to owners like partners vs double taxation for C-corps.

Funding – Some investors prefer structured entities like LLC, S-corp over sole props.

Ownership – Partnerships are ideal if multiple co-founders, LLC good for single or multiple owners.

Consult state regulations and an advisor to select the structure suiting your goals, scale and risk profile best. Complete all registration formalities accordingly.

Step 4: Build Your Initial Fleet Smartly

Having the right equipment mix makes or breaks your rental company. While starting small, aim to:

Target gap areas not served well by competition based on research.

Focus on most rented items with high turnover as money spinners initially.

Consider industry staples with wide use like backhoes, skid steers, excavators etc.

Purchase used units 1-3 years old in good condition at lower costs if budget allows.

Rent equipment temporarily to fulfill big orders until you buy your own.

Start with 5-10 main units and expand organically based on demand-supply analysis.

This balanced approach sets your business up for steady initial cash flows and growth.

Step 5: Establish Supplier Partnerships

Rentals require reliable source partnerships for equipment, parts and service support. Develop contacts with:

Leading construction equipment manufacturers for new purchases/extended warranties.

Used equipment resellers certified by OEMs for additional units.

Local repair shops and mobile technicians for maintenance services.

Accessory/attachment suppliers if diversifying product offerings.

Negotiate competitive equipment/parts pricing and favourable payment terms by committing decent order volumes. This allows leveraging supply chain relationships beneficially as your fleet scales.

Step 6: Purchase Necessary Insurances

Essential liability/asset protection policies for equipment rentals include:

General liability insurance covering bodily injury/property damages by rented units.

Inland marine/equipment floater policy covering owned assets against theft/damages.

Workers’ compensation covering employee injuries on the job.

Commercial auto insurance if delivering rented equipment.

Optional cover like pollution/professional liability depending on risk exposure.

Obtain quotes from multiple carriers and aim for high liability limits. Maintain insurance eligibility by following underwriter’s risk management guidelines closely.

Step 7: Develop an Optimal Pricing Strategy

Cost-based pricing factors in owning/operating expenses to determine profitable rates customers are willing to pay. Key considerations include:

Equipment costs – Purchase prices, financing interest and depreciation

Facilities costs – Rent, utilities, property taxes on the rental yard

Labour costs – Operator wages, technician salaries, maintenance labour

Operating costs – Insurance, inventory costs, marketing, G&A expenses

Maintenance reserves – Regular repairs and component replacements

Be competitive while ensuring fair margins to cover total costs. Try volume discounts for frequent users. Analyze industry rates and contractor feedback regularly to refine strategy as needed.

Step 8: Focus on Equipment Uptime

Regular maintenance is critical for lasting equipment performance and hitch-free rentals to keep customers happy. Develop a schedule addressing:

Daily pre-operation checks by operators

Preventive maintenance every 50-100 hours as per OEM guidelines

Schedule oil/filter changes, services as part of preventive maintenance

Thorough inspections and repairs during off-season months

Delegate tasks to qualified technicians and empower them with tools/parts to avoid rental downtime. Maintain digital records of all servicing for traceability and resale value accrual.

Step 9: Recruit an Experienced Team

Core staff requirements include experienced:

Equipment operators for rentals, deliveries, servicing

Mechanics and technicians to maintain high fleet uptime

Sales managers to handle enquiries, quotations and sales targets

Admin and accounting staff to process rentals, procurements and financials

Search through operator/mechanic certifications, construction experience and positive reviews. Offer competitive wages and benefits. Provide initial and ongoing skills training to motivate high-performers.

Step 10: Choose an Ideal Business Location

The location of your rental yard greatly impacts day-to-day operations and accessibility for customers. Consider the following factors when selecting a property:

Proximity to Construction Projects

Ideally choose an industrial area within 15-30 minutes of major ongoing building sites. This allows convenient equipment delivery and retrieval, saving clients’ time and money on transportation costs.

Visibility and Accessibility

Opt for a corner plot near junctions on main roads with high daily traffic. This enhances your business visibility and makes it easy for customers transporting equipment.

Property Size

Allow for indoor/outdoor space to safely park 5-10 initial machines with room to expand. A minimum 1-2 acre yard is advisable.

Zoning Regulations

Check local bylaws, the yard must be located in an industrial/commercial zone permitting heavy vehicle and equipment operations. Avoid residential zones.

Infrastructure Amenities

Select a lease/purchase property furnished with three-phase power supply and a portable toilet facility essential for mechanic work. Nearby trucking routes are a plus.

Location Costs

Review rent amounts or land prices in industrial areas you’re considering. Cheaper options help control overheads initially.

Security Features

Fence the perimeter and install locks, gates and Surveillance cameras important for protecting expensive assets outdoors overnight.

Inspect a few viable location options while keeping these core factors in view. An ideal spot boosts your availability to clients directly leading to higher equipment utilization and rentals over time.

Step 11: Develop Strong Marketing

Promoting your brand and services effectively is paramount. Here are key marketing tactics:

Website – with equipment list, rental process details, online booking

Social media – Post regular updates and videos on Facebook, Instagram, LinkedIn

Trade publications – Advertise in local construction magazines and newspapers

Direct mail – Send flyers to contractor offices about new equipment/offerings

Industry events – Exhibit at regional expos and conferences to build connections

Referral partnerships – Offer rewards to partner businesses for customer referrals

Signage – Erect signs near your yard for high visibility from main roads

Maintain online listings – on Google Maps, Yelp for local searches

Discount programs – Loyalty perks like volume/long-term discounts keep clients tied

Step 12: Launch and Continuously Improve

With all preparations finalized, you’re ready to begin operations. Maintain the momentum through:

Soft launch promotions to generate early orders and cashflows

Collection of regular customer and industry feedback

Periodic review of financials, processes, marketing and supply chains

Adding new equipment types and expanding rental capabilities

Strategic pricing tweaks based on market dynamics quarterly

Retaining skilled talent through training and competitive benefits

Exploring new regional markets as the business stabilizes

Constantly seek areas of improvement to stay ahead. Within a few years, your full-fledged construction equipment rental company will be up and thriving!

Conclusion

Starting a construction equipment rental business requires careful planning and execution, but with our 12-step guide, you’ll be well on your way to success. Remember to research your market, create a solid business plan, and choose the right equipment and location. Don’t be afraid to take the first step – with dedication and hard work, you can build a thriving business that generates consistent profits. Get started today!